What Is The Best Cut Pressure For Vinyl Cricut? Helpful Guide

Are you interested in finding out What Is The Best Cut Pressure For Vinyl Cricut?

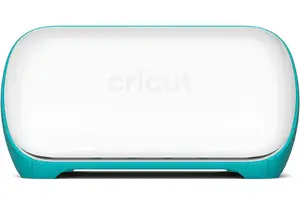

The popularity of vinyl cutting machines has grown over time as new developments in technology have made them more attractive. It is used to cut a wide range of materials including vinyl, papers, fabrics, foils, and even balsa wood (a lighter wood that is commonly used for model-building and crafts).

It is quite remarkable that these cutters can be used to cut through so many types of materials, but obviously, you will be curious as to what pressure setting is used to cut through different materials (particularly vinyl).

Here Are The 5 Best Selling Vinyl Cutting Machines This Year!

| Products | Rating | Price |

| Cricut Explore Air 2 | 9.8/10 [Editor's Choice] | Check Price |

| Cricut Maker Champagne | 9.6/10 | Check Price |

| Cricut Maker 3 | 9.8/10 | Check Price |

| Cricut Joy Machine | 9.6/10 | Check Price |

| Cricut Explore 3 Machine | 9.6/10 | Check Price |

You should know how to pick the right cutting pressure and how to adjust your Cricut pressure settings to achieve the best results for your designs.

Therefore, how much pressure do you need to apply to your vinyl cutter when cutting? In general, you should always use just enough pressure to cut through the material, but not too much that you begin to slice through the backing of the vinyl. You need to apply pressure depending on how thick and tacky the vinyl is. Materials that are thicker generally require more pressure.

As a starting point, consult the step-by-step guidebook or manual that comes with your machine to determine the Cricut maker pressure setting for vinyl. By trial and error, you will find the right setting for your project.

How To Determine The Cricut Pressure For Vinyl?

With these easy tips, you’ll not only be able to create excellent cutting craft projects, but you’ll also be able to save money on Cricut supplies.

Credit: chicagotribune.com

The Cricut Maker includes a few blades for which you cannot change the pressure of the cutting. They’re usually specialty blades. Whereas, in this article, we will talk about some of the standard blades – the deep-cut & the fine point blades, where the cutting pressure can be adjusted depending on your needs.

What Should The Cut Pressure Be For Vinyl?

There are different types of vinyl that need different cutting pressures. Following is a small list of different types of vinyl with blade types and their cutting pressures (specifically for the Cricut Maker Machine). These figures are taken from the official website of Cricut:

| Material Name | Cut Pressure | Multi-Cut | Blade Type |

|---|---|---|---|

| Premium Vinyl (Textured Metallic) | 152 | Off | Fine-Point |

| Non-Adhesive Vinyl (16 gauge) | 270 | Off | Fine-Point |

| Non-Adhesive Vinyl (20 gauge) | 300 | 2x | Fine-Point |

| Printable Vinyl | 107 | Off | Fine-Point |

| Premium Vinyl (True Brushed) | 113 | Off | Fine-Point |

Adjusting the Cutting Pressures:

In most instances, we just adjust the pressure of our Cricut blades to make them last longer. Or maybe we have a blade on our Cricut machine that is cutting the vinyl along with the backing of the vinyl, which is problematic as it will make the weeding process difficult or even impossible.

The machine will let you know if the cutting pressure needs to be adjusted. If you have a brand new blade, it is often excessively sharp that it will cut too deep. If this happens, you may need to reduce your pressure.

Credit: makersgonnalearn.com

Older, dull blades may not cut all the way through or may drag across the material as they cut. Some people assume that this means they have to replace their blade, but you can often extend its life by simply increasing the blade pressure.

Credit: makersgonnalearn.com

Some Important Terms To Understand:

Here are some concepts you need to understand so that you can cut without any issues.

Blade Pressure

The blade pressure of your machine is a measurement of how much downward force the machine applies to the blade to ensure it cuts through the material. Desktop machines usually have settings that can be changed according to what your project requires. These settings may even be referred to by a different name depending on the machine you use. For instance, it is referred to as “blade thickness” in some Silhouette models instead of “blade pressure”.

Here’s is a Great Fine-Point Blade for Sale on Amazon

Cutting Speed

The cutting speed of a Vinyl cutting machine also affects the quality of your cut, although you probably pay the most attention to the blade pressure. When something goes wrong in your cutting project, you might be tempted to start experimenting with blade offset or pressure, but it is often just a matter of cutting speed that is at fault.

Usually, it’s best to start slowly and increase your speed as you go. The cutting speed should definitely be slower if you have small details in your project. You can probably dial it down a bit if you start seeing tearing or skipping.

For cutters, the Vinyl cutter’s speed depends more on design than material; we generally recommend a starting point between 200 and 300 mm/sec, but as the cutting becomes finer and more detailed, the speed will have to be slowed down.

Here’s is a Great Vinyl Cutting Machine for Sale on Amazon

Test cuts and their importance

Testing each material individually is the only way to know how much pressure you need to apply. By performing test cuts beforehand, you can avoid the common problems that can occur when working with machines to cut your projects. A manual test cut should be performed on a small piece of vinyl, or whatever material you will be using.

There are lots of problems that can happen when cutting vinyl, like perforated skips, jagged lines, rounded corners, superficial cuts (the blade didn’t dig deep enough), or incomplete corners.

Credit: makersgonnalearn.com

If you play around with the settings during a test cut, you can customize everything to fit your project.

Check out our article – Is Cricut Printable Vinyl Waterproof? How To Seal Printable Vinyl

If everything is in order, you won’t have any problems when it comes to starting weeding the material (removing excess material that won’t be used in the final design).

Check Out This Video To Determine Cricut Maker Pressure Setting For Vinyl

FAQ’s

1- How should I choose the angle blades for my vinyl cutter?

The blades of cutters come in many different angles for different purposes. The most common blades are 45 and 60 degrees, although some manufacturers sell blades with a 30-degree angle as well. Generally, the 45-degree blade is the most popular. The blade works best with most thin materials, including vinyl. Moreover, if you have thicker vinyl and tougher material, a 60-degree blade is the best. Other than that, if you are interested to know about Cricut vinyl cut pressure, then you can head over to the article above which explains everything in detail.

Check out the article 10 Best Cricut Blades for Vinyl

2- When the Cricut blade cuts too deep, what should you do?

When your Cricut blade does not cut well or too deeply you may need to increase or decrease the cutting pressure. If this doesn’t work then you should replace it, because you may have chosen the wrong vinyl type or you may be using the wrong blade altogether.

3- What is the lifespan of a Cricut blade?

The Cricut premium fine point blade is expected to last between 12 to 18 months. Cutting heavy materials or using the blade daily will wear it down sooner. Moreover, if your blade does not cut well, even after cleaning and adjusting the settings, you should replace it.

Final Thoughts

The purpose of this article is to provide information on what Cut pressure for vinyl Cricut is appropriate. With this information, it will be easier to craft your designs and you will also not waste your supplies. The more you practice, the better you’ll remember the tips mentioned above. As soon as you gain enough knowledge about vinyl cutting pressures, creating crafts will become much faster. In addition, your cuts will look more crisp and professional.

Thanks for picking out our article on What Is The Best Cut Pressure For Vinyl Cricut?. We hope you find it useful.

Best deals on Amazon

Cricut Explore Air 2

Check Price on AmazonSilhouette Cameo 4

Check Price on AmazonCricut Joy Machine

Check Price on AmazonI specialize in writing tech-based product reviews for over 3 years now. My blogs aim to provide well-researched and informative content to help people make informed purchasing decisions.